When it comes to the fixtures in your retail locations, ensuring that every detail is just right is crucial. From displays to cashwraps and everything in between, the details of the fixtures in your space can make a big impact on your store’s success by positively or negatively affecting the customer experience. At GLW, our focus is on helping our clients create the best fixtures possible for their retail locations, and retail fixture prototyping is one of the key ways that we do this. But why should you take the time to go through the prototyping process when there are 3D renderings, drawings, and designs that can accurately depict what a finished fixture will look like? Let’s take a closer look at the prototyping process and how it can streamline fixture creation and improve quality within your retail location.

What Is A Retail Fixture Prototype?

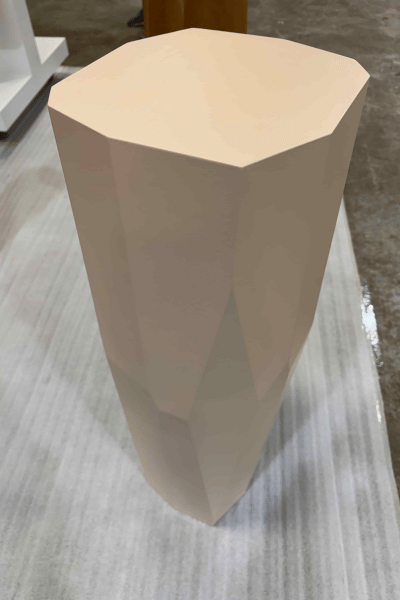

First, it’s important to discuss what a retail fixture prototype actually is. Before creating a fixture that gets permanently installed in your store or sending a design into mass production right off the bat, a prototype fixture is created. This prototype is a full-scale, functional sample of the fixture, produced before final manufacturing begins to serve as a tangible representation of the engineering drawings.

At GLW, our prototypes go through the complete engineering and production process to ensure that each unit functions and uses the exact materials (metal, wood, acrylic), finishes, and hardware intended for the final rollout. Creating prototypes this way is the most efficient way to ensure that you or your team can touch, feel, and test new fixtures effectively before final production and rollout.

Why Prototyping Is Essential Before Production

When prototyping retail fixtures, GLW crafts each unit using the measurements, materials, finishes, and features that are intended for the final design so that your team can fully test the fixture without committing long-term to a design that may or may not work. With prototyping, GLW clients also have the opportunity to create fixtures that have different configurations and features than the final rollout design, which is helpful for clients who are not sure about the final details within the fixtures. These different configurations can include variable shelf locations, technology integration, and other quality-of-life features that are better to finalize through experimentation. With these kinds of prototypes, clients can take the time to try out multiple configurations to see what works best for their location, uses, technology, and store processes.

How the Prototyping Process Works

Getting started with building prototypes begins just like it would with any other fixture build - a discussion with you to understand the design, needs, expectations, and requirements for the fixture. Whether you have a drawing already created, a complete list of materials and finishes that you’d like included, or just a verbal description of the fixture you have in mind, our team will work with you to get what you’re envisioning on paper and into our 3D design software. In our 3D renders, we’ll create the design the same way we would for a true production run – with notes for materials and finishes that are to be used in the final design, as well as any other notes for functionality, details, or features. When we’re finished with creating your design in 3D, we’ll get your approval to ensure that the prototype looks like what your store needs.

From there, the design goes into fabrication. Using the approved information from the design, we’ll fabricate the prototype fixture to specification. If it’s more cost-efficient or timely, prototypes can sometimes be created using less expensive materials or more readily available materials, but this depends on the options available, the timeframe needed for delivery, and other factors unique to each client and retail location. Finally, the prototype fixture is ready for your review! GLW ships prototypes to our clients and can install them directly into your space for testing and review. Additionally, for large prototyping projects or for specific types of projects, GLW can set up a testing and review space for you, providing the look and feel of the finished product without requiring you to change anything in your current stores before deciding on a design.

Display Wall Prototype by GLW - 3D Render

Fit, Finish, And Functional Testing

The most important benefit of prototyping is testing all of the features within a new fixture. Testing fit for your fixture is about more than just ensuring it will install in your space; the fixture also needs to fit by matching the branding, aesthetics, and overall feel of your business locations. Additionally, fitting the fixture should include merchandising the product – retailers should ensure that the fixture accommodates the merchandising needs of your business by testing it out with product arranged as it would be for sales, displays, and everyday use. The finishes on the prototype, such as hardware, lighting, colors, and more, can get lost in translation when you’re just looking at drawings or renderings. By experiencing these finishes in real life, you can more easily decide how well they work together or if any of them need to be changed.

Whether it’s integrating technology for capturing sales, holding and storing supplies for employees, or fulfilling safety and security standards, testing the functionality can help you determine any other adjustments that may need to be made. For instance, specialty retail locations such as jewelry stores or cannabis dispensaries need display cases that effectively display products and packages while also providing the security required for these products.

Common Issues Prototypes Catch Early

Issues that clients often catch during prototyping are usually in one of two categories: ergonomics and technology.

With ergonomics, clients often find that fixtures, once installed, don’t quite feel right. This could be due to product being placed too high or too low, or it could be how the fixture functions for the people within the store. Once the fixture is physically reviewed, it can be easy to see that the original design is too large for the product it’s designed to hold, it’s inaccessible to customers, or that the employees using the fixture regularly would experience discomfort from having to stoop or reach for items that need to be regularly accessible.

As far as technology issues, testing prototypes can often reveal issues such as keyboard trays that are not deep enough or a dunnage rack that is too small. Conversely, the prototyping process can reveal larger issues, such as a register or cashwrap station that doesn’t actually fit the technology needed for the POS system.

How Prototyping Speeds Up Approvals

While this may seem counterintuitive, taking the time to prototype can actually speed up your company’s success with new fixtures because the process allows for testing, adjustments, and real-life review. Throughout the prototyping and testing process, questions about the features of a given fixture will be answered before installation. By experiencing prototypes, clients can build more trust and confidence in the final design and the quality of the finished product, allowing decision makers to make more informed choices about the fixtures created for retail locations.

What Happens Without Prototyping

Creating fixtures without going through the prototyping process can become more expensive in the long run. For instance, a fixture with a shelf that doesn’t quite fit product can be modified after installation, but if this fixture was created the same way across multiple retail locations, each one of these fixtures needs to be modified. The cost of the modification alone can add up, but it’s also important to consider interrupted open hours, the cost of dismantling the current fixture, additional materials, and other issues that may present along the way.

How Retailers Can Run A Useful Prototype Review

While the prototype review process can look different for each client and each location, there are a few key factors that help to make the process successful:

- Functionality: Does the prototype fulfill the needs and requirements of the original design? Does it fit the products it is going to house? How will the functionality of the design be impeded or improved with small adjustments to any sections?

- Aesthetics: Are there any features that look out of place? Is the color and style in line with the branding for your company and store locations?

- Technical Features: Examine the lighting within the fixture and check how technology such as POS systems, security systems, tablets, or inventory portals integrate. Does all of the technology mesh with the fixture? Are any of the technical features affected by the design?

- Customer Impact: Is the fixture appealing or inviting to the customer? Does it encourage shoppers to stop and interact with the product, or does it show off the product effectively?

By asking these questions and recording the answers, your experiences with the prototype, and any suggestions, concerns, or thoughts about the product, you and your team can conduct a successful prototype review.

Whether it’s testing new cashwrap configurations, building new security cases for jewelry, or modernizing your product displays, ensuring a successful fixture rollout begins with prototyping. By testing the product thoroughly before final installation, you and your team can address potential problems, customize the fixture to your brand’s aesthetics, and create a truly functional design that positively impacts your business.