Custom retail fixtures, such as display cases, POS tops, and shelving, are crucial components of brand identity and enhance the shopping experience for customers. At GLW, we have decades of experience manufacturing fixtures using a wide variety of material types.

Custom retail fixtures, such as display cases, POS tops, and shelving, are crucial components of brand identity and enhance the shopping experience for customers. At GLW, we have decades of experience manufacturing fixtures using a wide variety of material types.

In this blog post, our experts explain a few key factors to help you specify the best fixture for your retail environment.

#1: Durability and quality

When budgets are restricted, some retailers opt for lower-quality materials to cut costs. However, in many cases, premium materials will save money over the lifetime of the fixture–because they will last longer, withstand more wear and tear, and require less maintenance.

At GLW, our expert team can help you determine which components of your fixture can use cheaper materials and which require premium. For example, solid wood is crucial for structural elements such as doors, or for fixture edges that face more exposure. Value-engineer your project to select cheaper wood veneers for interior components, but use real wood when necessary to make sure your fixture maintains its aesthetic and functionality for years to come.

#2: Material finish

There are a huge array of custom finishes to choose from, including painted-on textured finishes, stained finishes, clear finishes, wire brush finishes, and more. Choose a finish that both matches the aesthetic of your brand and retail environment, and also protects your fixture from wear and tear. For enhanced durability, opt for a hard crystal finish.

At GLW, our standard finish is a 1/15th-sheen matte finish, but our in-house paint shop experts will work with you to achieve your desired look. We send finish samples and drawings for approval before manufacturing begins.

#3: Sustainability

A brand’s environmental footprint has become increasingly important to consumers over the last several years. When specifying your fixture, partner with a supplier who will source eco-friendly, 100% recyclable materials.

#4: Cost

The cost of fixture materials depends on many variables: not just the raw material cost, but the finish cost, manufacturing cost, maintenance costs, and overall material longevity.

If your budget is tight and you’re looking for ways to value-engineer your project, consider opting for reconstituted veneers, powder-coated metals, acrylics, and plastic laminates.

#5: Maintenance

Specify materials that are easy to clean and will reduce lifetime maintenance costs. Wood veneers are less prone to warping compared to solid wood, and will require less maintenance. Stone is often selected for POS tops because of the material’s high durability and low maintenance. Powder-coated metals are easier to clean than plated or painted metals, and also less likely to chip or fade.

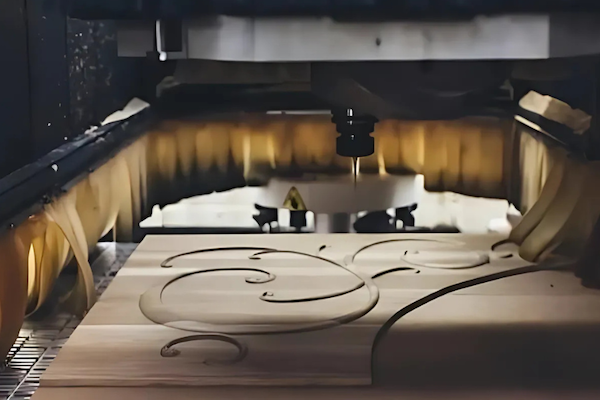

GLW’s material capabilities

Our in-house team of craftsmen has expertise with a wide range of material types. Here are a few advantages of each:

Wood

Solid wood is more durable than veneer, and is best for fixture edges and structural building components. We work with straight edge or live edge wood, and will recommend and source a high-quality wood type that fits your budget.

Veneer

Veneers tend to be cheaper than solid wood and will last longer without warping. We use miter folded pre-finished veneers to simulate solid wood.

Glass

Most of our customers prefer low-iron glass. We provide in-house UV bonding, creating crystal-clear glass fixtures for museum display cases, jewelry fixtures, and other display environments.

Metals

Metal fixture components can be either structural or decorative. For structural metal, we recommend powder coating for enhanced durability and a reduced environmental footprint. Decorative metal often has a plated finish and contributes a modern industrial look to your retail environment.

Corian Solid Surfaces

We have expertise sourcing and working with almost any type of solid surface, including natural stone, manufactured stone, and acrylic polymer. These materials are popular for POS tops and counters due to their durability and ease of maintenance.

Acrylics and plexiglass

Acrylics are cheaper than glass, but also less durable. With our in-house UV bonding glass capabilities, fewer retailers are opting for acrylics–but it may still be an effective choice to reduce costs for your fixture.

Plastic laminates

Plastic laminates are best for expedited orders, since they do not require any paint shop time. They also tend to be lower-cost than wood or paint-finished materials. We have in-house plastic laminate press, so we can manufacture custom materials that reflect your brand’s unique identity.

Upholstery and leather

Our in-house leather specialists will create fixtures that add to the luxury of your space.

Want to learn more?

If you have questions about specifying the right materials for your retail fixture, our team is ready to consult with you. Contact us today!